Our Product Categories

Drilling Rig Spares

Complete range of drilling rig components and replacement parts for optimal performance.

Tubing Tongs

Heavy-duty tubing tongs designed for reliability and precision in oilfield operations.

Hammer Unions

High-pressure hammer unions and fittings for demanding industrial applications.

Shale Shaker Baskets

Durable shale shaker baskets engineered for efficient solids control systems.

Slip & Tong Dies

All types of slip and tong dies manufactured to exact specifications.

Machinery Spares

Comprehensive range of industrial machinery spare parts and components.

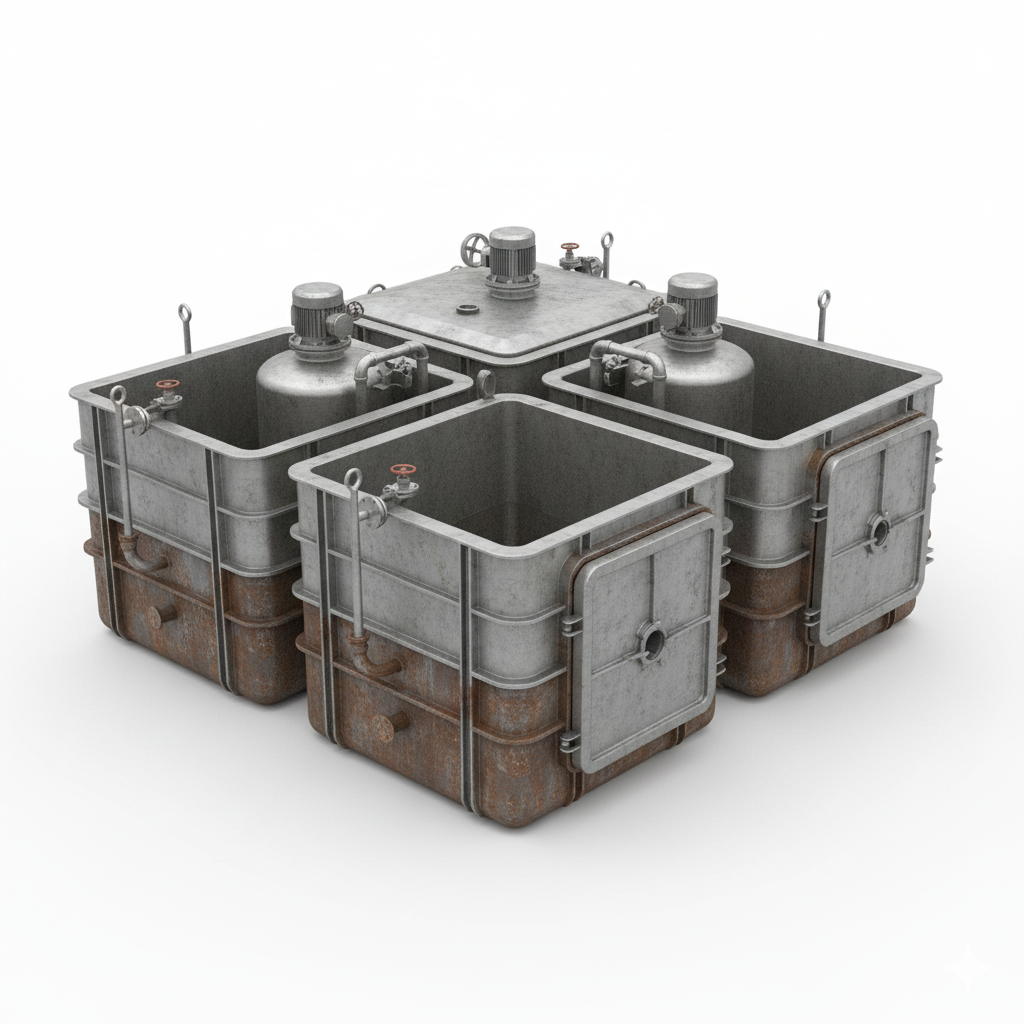

Mud Tanks

High-capacity tanks engineered for reliable drilling fluid handling.

Winch Machine & Spares

Heavy-duty winch systems with complete support for spares and upgrades.